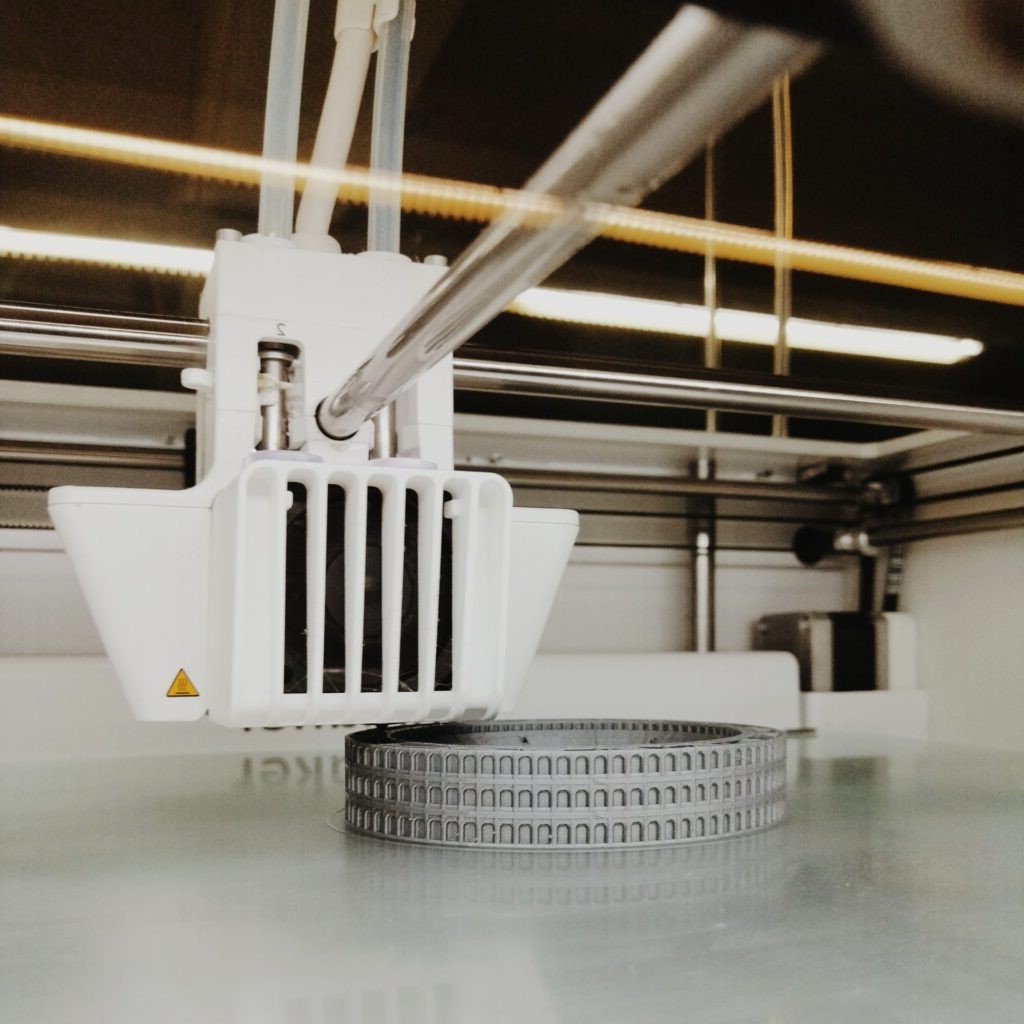

Hand-On Industries offers 3D printing solutions to meet the component/ assembly needs of our customers. Using modern 3D printing technology and in-house CAD facilities, we manufacture components/ assemblies made from 3D printing standard plastics with flexibility and geometry not possible when utilising traditional subtractive manufacturing processes.

Expertise in 3D printing allows us to produce components that meet the exacting standards expected by our customers. Any form of design data (from hand sketches to full CAD models) can be used to produce parts. Whether a prototype or full production run is required, we will deliver quality results on time.